An Indian subsidiary of a global industrial manufacturing firm drastically

Read MoreYour Partner in driving Procurement & Supply Chain Excellence

What We Do?

Help drive higher Profitability through global best practices in Procurement & Supply Chain.

Procurement Transformation

Supply Chain Excellence

Data Quality & Spend Analysis

Supply Chain Learning Center

MRO Excellence

Working Capital Management

Sustainability

In a world with shorter product cycles, growing global competition and an increased risk of supply chain disruption, coupled with ever increasing external supplier spend, companies must use Strategic Sourcing to create sustainable competitive advantage. We partner with our clients to create and advance their strategic sourcing excellence.

To assess and minimize risks related to the external spend, an organization must look holistically at the contract management life cycle – from negotiation & sign-off to contract execution and exit.

Procure to pay (P2P) is the end-to-end process that covers all the steps from initiation of the requirements by a user to the payment to the supplier. Of course, the process on-paper looks easy but each step in the process could be problematic and painstaking for your end-users – for example, a manual requisition process or a long approval chain or a delayed supplier payment.

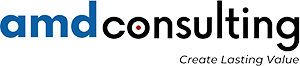

Supply chain leaders have a fundamental responsibility to continually monitor and improve the performance of their supply base. There can be no doubt that the quality of the entire supply chain is directly affected by supplier performance. Good suppliers enable an organization to achieve business objectives through – timely deliveries, price reductions, and product & service quality.

High-performing supply chains yield several beneficial outcomes – high customer satisfaction, ability to adjust quickly to external events, a high return on capital for supply chain assets employed and consistent productivity improvements that enable reinvestment back into the business.

Modern supply chains are increasingly interdependent. While globalization, extended supply chains, and supplier consolidation offer many benefits, they can also make supply chains more complex, fragile, and susceptible to disruptions.

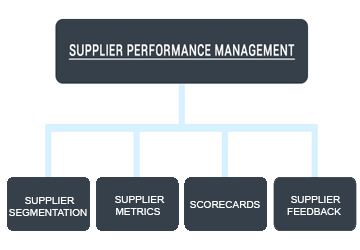

Many organizations routinely struggle to meet customer expected lead times due to lack of visibility into demand, high SKU count, and a challenging supply chain with long lead times. This often results in lost sales due unacceptable service levels and high inventory levels to support sales.S&OP process aligns an organization across all relevant cross functions to optimize operational capacity by balancing demand and supply.When done well, it allows a business to capture

While inventory is classified as an asset, many organizations fail to manage inventory optimally as they would manage other asset. Inventory optimization is not an isolated or static activity. It requires an integrated approach with other supply chain activities to effectively respond to factors such as changing demand patterns.

The pandemic, trade wars, and severe storms: these are just a few of the disruptions recently churning markets. We can see the impact of these disruption on entire supply chain. Especially, the logistics sector is the one got hit severely and now undergoing fast paced transformation.

A healthy supply chain is synonymous with healthy data, and many of the process improvement initiatives begin with the data itself. Right from sourcing of goods & services to inventory management, and logistics, quality of data & analytics is immensely critical to value creation – be it cost reduction or risk mitigation.

Clean and accurate data is a must for insightful data analysis. Data cleansing and enrichment is critical step in the overall data quality enhancement process. The process involves consolidating data from different systems, identifying relevant data, and cleansing & enriching it to create a master database.

Data Classification is all about categorizing and organizing data for better analysis and decision making. A well-classified data can dramatically improve analytics enabling insights and improvement opportunities such as cost reduction etc.

In today’s world of faster product cycles, growing global competition and increased risk of supply chain disruption, companies need to know how to use strategic sourcing as a competitive advantage. Global sourcing or external spend can account for a large portion of the overall costs in many industries.

Excellence in Procurement & Supply Chain Management requires continual investment in talent development. Without sustained efforts in building “Capacity & Capability” that are aligned with ever changing business world, an organization will be handicapped in creating long term value.

While we find several online & offline courses on procurement & supply chain management that are readily available, there always exists a gap in assimilation of such content vis-à-vis practical industry experiences. Hence, it is critical to design the right content that is customized to a specific organization’s needs and working environment, thereby improving overall learning and the training ROI.

MRO (Maintenance, Repair & Overhaul) spend management can be a daunting task for many organizations due to its fragmented and complex nature with very large number of SKUs across multiple sub-categories, most of these items being critical to a company’s operational performance.

MRO (Maintenance, Repair & Overhaul) spend management can be a daunting task for many organizations due to its fragmented and complex nature with very large number of SKUs across multiple sub-categories, most of these items being critical to a company’s operational performance.

Every business needs cash to fund everything, from running operations to exploring avenues of growing the business. Having visibility into overall working capital performance can drive higher profitability.

Working capital optimization is needed to improve company’s daily operations – reduce cost of borrowing, free up cash for investment, and reduce operational bottlenecks caused by the need to meet current liabilities.

ESG, or Environmental, Social, and Governance, refers to the three key factors used to measure the sustainability impact of an organization. These three parameters individually along with the overall framework, holistically show how an organization impacts and gets impacted by the outside world. ESG has now started to become a mandate globally for the companies to do sustainable business.

Sustainable procurement or supply chain involves integrating environmental, social, and governance (ESG) considerations into the procurement process, ensuring that procurement decisions not only meet organizational needs but also contribute to positive social and environmental outcomes.

Who We Are?

Our Belief

Our mission is to help create procurement & supply chain excellence through

world class thinking in all areas of the supply chain.

world class thinking in all areas of the supply chain.

Our Approach

We strongly believe in systems thinking approach to problem solving and strive to provide holistic solutions.

We strongly believe in systems thinking approach to problem solving and strive to provide holistic solutions.

Our Team

An experienced, versatile, and highly motivated team ready to assist solve your critical supply chain problems.

An experienced, versatile, and highly motivated team ready to assist solve

your critical supply chain problems.

your critical supply chain problems.

Who We Are?

Our Belief

Our mission is to help create procurement & supply chain excellence through

world class thinking in all areas of the supply chain.

world class thinking in all areas of the supply chain.

Our Approach

We strongly believe in systems thinking approach to problem solving and strive to provide holistic solutions.

We strongly believe in systems thinking approach to problem solving and strive to provide holistic solutions.

Our Team

An experienced, versatile, and highly motivated team ready to assist solve your critical supply chain problems.

An experienced, versatile, and highly motivated team ready to assist solve

your critical supply chain problems.

your critical supply chain problems.

Our Customers

Case Studies

Procurement Coaching & Mentoring

Training program based on Coaching & Mentoring model enhanced cross-category

Read MoreMRO Spend Analysis

An Indian subsidiary of a leading global pharmaceutical company uncovered

Read More