Sales & Operations Planning

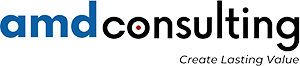

Many organizations routinely struggle to meet customer expected lead times due to lack of visibility into demand, high SKU count, and a challenging supply chain with long lead times. This often results in lost sales due unacceptable service levels and high inventory levels to support sales.S&OP process aligns an organization across all relevant cross functions to optimize operational capacity by balancing demand and supply. When done well, it allows a business to capture operational efficiencies by proactively adjusting capacity to changing forecasts.

It is challenging to implement S&OP process and more challenging to maintain. It requires very high level of diligence to produce clear and consistent benefits.

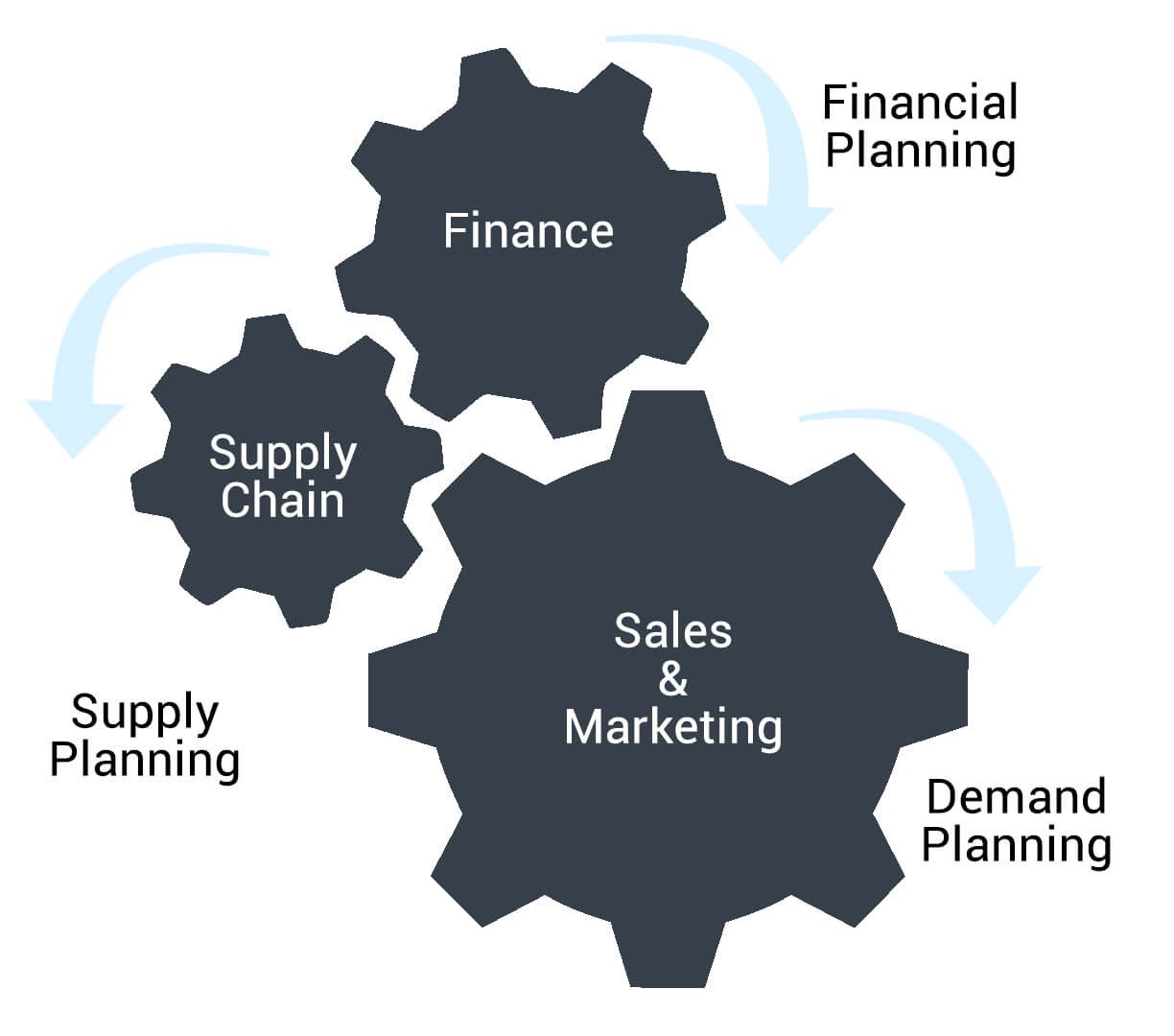

We help organizations in implementing & maintaining S&OP process through granular level tracking and management cadence as below to achieve the objectives –

- Demand Planning & Forecasting Meeting

- Supply Chain & Ops Planning Meeting

- Risk treatment (4T model – Terminate, Transfer, Treat, Tolerate)

- Balancing Meeting (Supply / Demand Meeting)

- Executive Meeting

S&OP – A critical success factor in today’s highly volatile business world

What We Do

Procurement Excellence

Supply Chain Excellence

Data Quality & Spend Analysis

Supply Chain Learning Center

MRO Excellence

Working Capital Management

Sustainability