Managing inventory has always been a critical and challenging part of a supply chain involving several risk factors and directly impacting a company’s profitability and customer experience. While management theories are full of inventory optimization techniques such as Kanban, TOC etc., not much focus is seen on supply chain risk assessment at granular level and its impact on inventory management. Additionally, there is a cultural aspect too, to managing right level of inventories in that a company with risk averse culture would want to keep more inventory than is optimal.

How difficult it is then to institutionalize supply chain risk assessment and make informed and optimal decisions on inventory levels? In general, the notion of trying to determine all various things that ‘could’ go wrong with supply chain is certainly a difficult task to undertake. While no one has a crystal ball and can foresee every single issue that may (or may not) arise, it is important to still make a discerned effort into assessing as many conceivable risks and derive action plans to mitigate them to reduce operational (inventory carrying) costs. With advances in data analytics as well as evolved risk management techniques, today it is very much possible to apply robust risk assessment to a supply chain and optimize inventory.

A recent discussion with a global automotive tier-1 components manufacturer highlights the point that inventory levels are not always decided based on systematic risk assessment or in a scientific way. This company has been keeping their finished goods inventory (VMI) of over 8 weeks at the behest of a large client (OEM). Further probe established that such an inventory level was demanded based on a fire incident that kept the plant out of production for over 2 months. There is a fundamental flaw in the above. Firstly, one shouldn’t plan routine inventory levels based on such a rare event. Also, today there are advanced fire detection and control technologies that can safely eliminate or significantly reduce such a risk. In any case, keeping 8 weeks inventory is a sin, when global best-in-class companies in automotive components vertical manage finished goods inventory levels of under 1 week.

Here is how one can systematically apply Supply Chain Risk Management concepts and link to inventory optimization. Firstly, to get a deeper understanding of the operations, one must look at various core business processes (internal to organization) that are involved in Inventory management, typically – Procurement, Manufacturing, Product Design and Sales & Marketing. Next, explore key success metrics associated with all these business processes and the risks that prevent them from attaining the objective. Also, one need to also explore external influencing factors related to suppliers, economic changes, natural calamities etc.

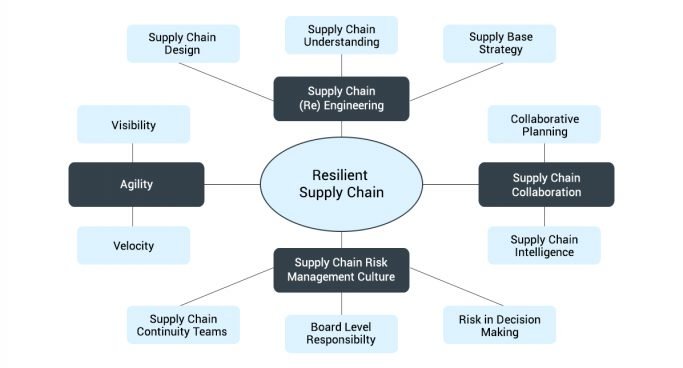

Next, a Supply Chain Risk Management framework as shown below will come in handy to address questions such as –

- How to devise the strategies to mitigate the risks at an organizational level.

- How to implement a culture of risk management across the business units.

- How to sustain the best practices & strategies over a longer term.

- What are the tools available to identify risks associated and manage it.

Supply Chain Risk Management Framework

Such a framework helps in establishing risk awareness & management culture throughout the supply chain organization to minimize the risks as well as develop resilience against any unforeseen adverse impact, both ways helping improves the profitability. Supply Chain Risk Management offers a robust methodology that looks beyond just numbers and includes qualitative factors and human elements thereby providing a holistic view around managing risks.

For managing risks, particularly related to inventory, there are two broad situations –

- Risk of stock-out (Adverse impact on revenue and customer experience)

Supply chain risk assessment at the item level can help companies to reduce stock-out possibility (risk prevention) as well as help reduce potential adverse impact in case stock-out happens due to unavoidable circumstances (resilience).

- Risk of working capital lock (Adverse impact on profitability)

A maniacal focus on inventory levels is necessary and senior leadership must keep this on its radar, always. Continual assessment through a centralized inventory control along with regular decision on eliminating obsolete inventory is critical.

In conclusion, SCRM offers a new and holistic way of considering and managing the inventory levels in a fast-paced supply chain environment today. Traditionally, risk management has largely been associated with actuarial work specifically related to insurance and to some extent in hedging risk related to commodities and international finance. Now the same principles can be applied to supply chains worldwide to make them more robust, more resilient, and more profitable.

Other Insights

Global Strategic Sourcing from India GICs – Front Ending from Back Office

Our experience over the last decade & half in working with several multi-national technology companies with India GICs (Global In-house...

Effectively Managing Contingent Workforce in Software Industry

Over last decade half the contingent workforce has become increasingly important and a strategic part of the total workforce of...

Business Risk Management – Look Beyond Contract Compliance Tools

In the world of contracts management two trends are running parallel, however a meaningful common solution is not in sight...

Supply Chain Agility – Need of the Hour

In a continually volatile marketplace that we experience today, Agile Supply Chain is not an option but a necessity for...